Descrição do produto:

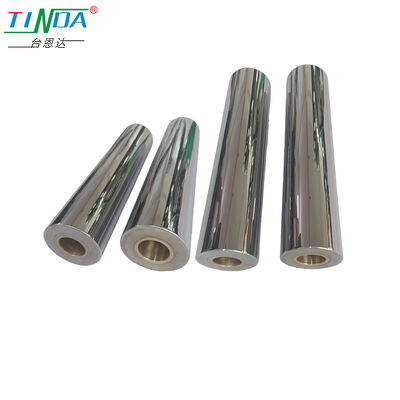

O Roller de Metal Industrial, conhecido na produção como Super Mirrored Chrome Steel, representa o auge da engenharia de precisão e da tecnologia de tratamento de superfície.Fabricado a partir de uma selecção de materiais de alta qualidade, incluindo aço #45, de alumínio e de aço inoxidável de qualidade superior, tais como 304L, 316L, 2205, nomeadamente a classe de rolos de aço inoxidável super 904L,Este produto foi concebido para satisfazer as exigências rigorosas da indústria aeroespacialCada rolo é submetido a um processo de tratamento de superfície avançado, com um acabamento cromado que não só aumenta a durabilidade, mas também proporciona uma aparência espelhada visualmente impressionante.

Uma das características definidoras deste rolo de cromo é a sua excepcional precisão dimensional, fabricado com uma tolerância de apenas 0,02 mm.O rolor de metal industrial garante um desempenho suave e confiável em aplicações aeroespaciais críticas onde a precisão é primordialEsta tolerância apertada contribui para reduzir o desgaste, melhorar a eficiência e prolongar a vida útil, tornando-o um componente indispensável nas máquinas aeroespaciais e nas linhas de fabrico.

Os tratamentos de superfície aplicados a este rolo elevam as suas propriedades mecânicas a novas alturas.que é vital para componentes expostos a ambientes adversos e a tensões operacionais contínuasA especificação do rolo de aço HV700 indica um nível de dureza de 700 HV, um ponto de referência de resistência à abrasão.Tal tratamento garante que o rolo mantenha a sua integridade e desempenho funcional durante períodos prolongados, mesmo nas condições mais exigentes.

A selecção do material desempenha um papel crucial no desempenho do rolo.A incorporação de aço inoxidável 904L de qualidade de rolos destaca-se pela sua notável resistência à corrosão e ataque químicoAlém do 904L, a utilização de aço inoxidável de graus 304L, 316L,e 2205 acrescenta versatilidadeA inclusão das opções de alumínio e aço #45 amplia ainda mais a aplicabilidade do produto.oferecer soluções que equilibrem o peso, resistência e condutividade com base nas necessidades do projecto.

O Roller de Metal Industrial é projetado para suportar rotação de alta velocidade e capacidades de carga pesada, atributos críticos para processos de fabricação aeroespacial, como moldagem de precisão,revestimentoA sua superfície cromada minimiza o atrito e a geração de calor durante o funcionamento, o que não só melhora a eficiência, mas também reduz os custos de manutenção e o tempo de inatividade.Isto torna-a uma solução rentável para os fabricantes aeroespaciais que buscam uma produtividade óptima sem comprometer a qualidade.

Em resumo, o Roller Metal Industrial com o seu nome de produção Super Mirrored Chrome Steel é um componente sofisticado e de alto desempenho adaptado para a indústria aeroespacial.O seu tratamento de superfície superior, incluindo o revestimento de cromo e a dureza do rolo de aço HV700, combinado com uma seleção de materiais robustos como o rolo de aço inoxidável 904L, oferece durabilidade inigualável, precisãoe confiabilidadeCom uma tolerância tão apertada como 0,02 mm, este rolo é projetado para se destacar em ambientes onde a precisão e a resiliência não são negociáveis.Outros aparelhos e aparelhos para máquinas de lavar roupa, este rolo de cromo é um testemunho da engenharia avançada e ciência dos materiais, garantindo desempenho duradouro e eficiência operacional excepcional.

Características:

- Nome do produto: Rolha de metal industrial

- Modo de moldagem: molde de forja ou personalizado

- Material: aço cromado super espelhado

- Nível de vibração: baixo

- Forma: cilíndrica

- Aplicação: Indústria aeroespacial

- Inclui rolos de aço de alta qualidade para maior durabilidade

- Características de rolos revestidos de zinco para uma excelente resistência à corrosão

- Fabricado com rolos de aço 2205 para resistência e desempenho superiores

Parâmetros técnicos:

| Nome da produção |

Aço cromado super espelhado |

| Materiais |

Metal; #45 Aço; Rolante de alumínio; Rolante de aço inoxidável; Aço inoxidável 304L, 316L, 2205, 904L |

| Tratamentos de superfície |

Cloreto de potássio |

| Tolerância |

0.02 mm |

| Modo de modelagem |

Forja de moldes ou personalizados |

| Nível de vibração |

Baixo |

| Forma |

De forma cilíndrica |

| Aplicação |

Indústria aeroespacial |

Aplicações:

O TINDA Industrial Metal Roller, modelo TINDA-Steel-868, é um produto versátil e de alto desempenho concebido para uma ampla gama de aplicações industriais.Originário da CHINA e certificado pela SGS, este rolo é fabricado com precisão, garantindo uma tolerância de apenas 0,02 mm. Sua construção robusta usando materiais de primeira qualidade, tais como #45 aço, alumínio, aço inoxidável 304L, 316L, 2205,e 904L garante durabilidade e desempenho duradouroO rolo é submetido a tratamentos de superfície como cromagem para melhorar a resistência à corrosão e proteção contra desgaste, tornando-o ideal para ambientes operacionais exigentes.

Uma das principais aplicações do TINDA-Steel-868 é nos sistemas de transportadores, onde a variante de rolos revestidos de zinco é amplamente utilizada.Este revestimento de zinco fornece proteção adicional contra ferrugem e desgaste ambientalO baixo nível de vibração do rolo garante uma operação suave e silenciosa,que é essencial nas linhas de produção automatizadas para manter a eficiência e reduzir a poluição sonora.

Outro cenário crítico para a utilização do rolo de metal industrial da TINDA é em máquinas pesadas, onde são necessários rolos de aço HV700.,permitindo que o rolo resista a fortes tensões mecânicas e à abrasão, o que o torna perfeito para aplicações em siderúrgicas, equipamentos de mineração,e sistemas de transporte pesado em que a fiabilidade e a resistência são primordiais.

Além disso, a variante de rolos de aço 2205 é muito procurada nas indústrias de processamento químico e marítimo devido à sua superior resistência à corrosão e propriedades mecânicas.O material duplex de aço inoxidável 2205 garante um excelente desempenho em ambientes adversos que envolvem exposição a sais, ácidos e temperaturas extremas.

Com uma capacidade de abastecimento de 10,000A TINDA pode satisfazer as várias necessidades de produção de forma eficiente.O produto está disponível com opções de embalagem, como caixa de madeira ou embalagem de exportação padrão para garantir a entrega seguraOs termos de pagamento são flexíveis com T/T aceito, e o tempo de entrega é tipicamente de 7 dias ou conforme aconselhado.permitir que empresas de todas as dimensões se beneficiem deste rolão industrial de alta qualidade.

Em geral, the TINDA-Steel-868 industrial metal roller is designed to perform reliably in diverse application occasions ranging from conveyor systems and heavy-duty machinery to chemical processing and marine environmentsA sua combinação de materiais avançados, fabricação precisa e tratamentos de superfície especializados tornam-na um componente indispensável nas operações industriais modernas.

Personalização:

Marca: TINDA

Número de modelo: TINDA-Steel-868

Local de origem: CHINA

Certificação: SGS

Quantidade mínima de encomenda: 1

Preço: Negociação

Detalhes da embalagem: Caixa de madeira ou embalagem de exportação padrão

Prazo de entrega: 7 dias ou A ser informado

Termos de pagamento: T/T

Capacidade de abastecimento: 10,000,000 pcs/mês

Os nossos rolos metálicos industriais oferecem serviços de personalização excepcionais adaptados às suas necessidades específicas.tornando-os ideais para a indústria aeroespacial.

Fornecemos uma variedade de opções de materiais de alta qualidade, incluindo 316L rolos de aço, 304L rolos de aço, e super rolos de aço inoxidável 904L, garantindo durabilidade superior e resistência à corrosão.

Os tratamentos de superfície incluem cromagem para melhorar a resistência ao desgaste e a longevidade.

Com a certificação SGS, os nossos produtos garantem qualidade e fiabilidade.A nossa capacidade de fornecimento de 10 milhões de peças por mês garante a entrega atempada.

A embalagem é cuidadosamente feita em caixas de madeira ou em embalagens de exportação padrão para proteger os rolos durante o transporte.

Escolha a TINDA para as suas necessidades de rolos metálicos industriais e beneficie dos nossos serviços de personalização especializados concebidos para oferecer desempenho e qualidade.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!